Pravahi Hydraulics - Injection Molding Machine

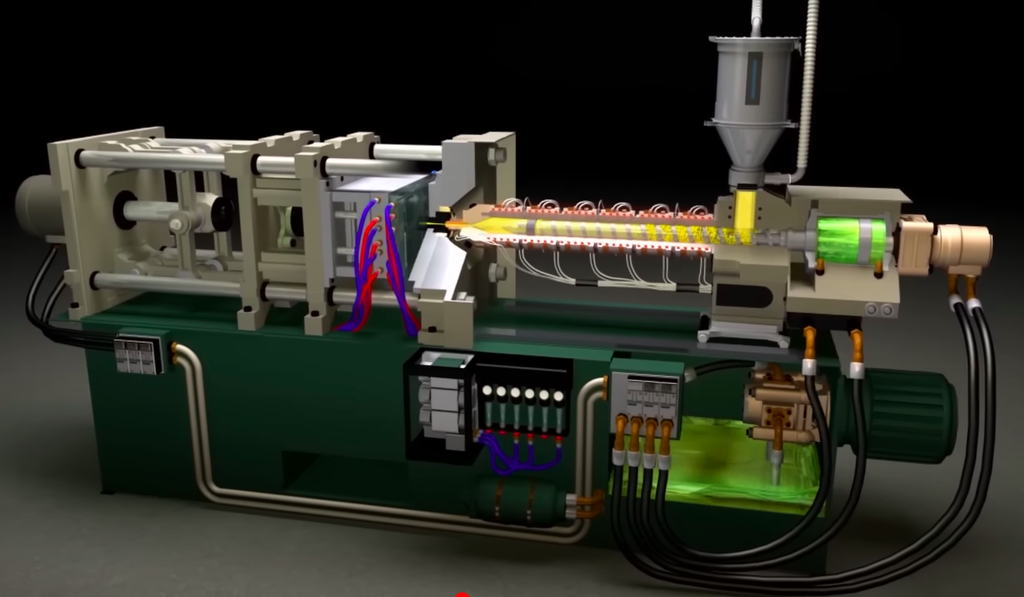

Injection molding machine Image credit: PaulsonTraining

An injection molding machine is a manufacturing tool used to produce precise plastic parts by injecting molten plastic into a mold, where it cools and solidifies. In India, hydraulic injection molding machines are widely used due to their affordability and ability to deliver high clamping forces for industries like automotive, packaging, medical, and electronics. This article focuses on the hydraulic system design of injection molding machines, covering categorization, specifications, hydraulic components, functions, requirements, design considerations, and relevant standards, with detailed insights into common hydraulic designs in the Indian market.

Overview

Injection molding machines perform key functions—clamping, injection, screw rotation (plasticizing), ejection, and carriage movement—often powered by hydraulic systems in India due to their cost-effectiveness and robustness. Hydraulic systems use pumps, valves, cylinders, and motors to deliver precise force and control, critical for high-volume production. This page emphasizes the hydraulic system’s components, functions, requirements, and design considerations, tailored for India’s manufacturing needs, while adhering to international standards for safety and performance.

Categorization of Injection Molding Machines

Injection molding machines are categorized by drive system, clamping mechanism, configuration, and application, with hydraulic systems playing a central role in many designs, particularly in India.

By Drive System

- Hydraulic Machines: Use hydraulic pumps and motors to power all functions, offering high clamping forces (500–8000 tons) at lower initial costs, making them prevalent in India.

- Electric (All-Electric) Machines: Use servo motors for all functions, providing high precision and energy efficiency but less common in India due to higher costs.

- Hybrid Machines: Combine hydraulic power with electric servo motors, balancing cost and efficiency, increasingly adopted in India for precision applications.

By Clamping Mechanism

- Toggle-Type: Employs a mechanical toggle system driven by hydraulic cylinders, popular in India for fast cycle times in medium-tonnage machines (100–2000 tons).

- Two-Platen: Uses hydraulic cylinders to apply force between two platens, ideal for large molds (up to 55,000 kN), growing in India’s automotive sector.

- Direct Pressure: Applies direct hydraulic force, used in specialized high-force applications.

By Configuration

- Horizontal: Dominant in India for high-volume production, with hydraulic systems driving clamping and injection.

- Vertical: Used for insert molding in electronics and automotive, with compact hydraulic designs.

By Application

- General-Purpose: Versatile for various plastics, relying on cost-effective hydraulic systems.

- Precision: High-accuracy for tight tolerances (±0.025 mm), often hybrid in India.

- High-Speed: Fast cycles for packaging, using hydraulic accumulators.

- Large-Part: High clamping forces for automotive parts, driven by robust hydraulics.

- Multi-Component: Multiple injection units for multi-material parts, supported by complex hydraulic circuits.

Common Hydraulic Designs in India

In India, hydraulic injection molding machines dominate due to their affordability and ability to handle high-force applications. Common design characteristics include:

- Cost-Optimized Hydraulics: Use variable displacement piston pumps or vane pumps for cost-effectiveness, often locally sourced to reduce costs while meeting ISO 9001 quality standards.

- Toggle Clamping: Widely adopted for medium-tonnage machines (100–2000 tons) due to fast cycle times and compact hydraulic designs, suitable for India’s high-volume production.

- Horizontal Configuration: Preferred for automotive and packaging, with hydraulic systems optimized for automation integration.

- Servo-Hydraulic Systems: Increasingly used for 40–60% energy savings, especially in mid-range machines, addressing India’s focus on energy efficiency.

- Simplified Maintenance: Modular hydraulic components and accessible test ports to minimize downtime in India’s high-cycle manufacturing environments.

- Automation Integration: Hydraulic systems designed with interfaces for robotic part removal, aligning with India’s growing automation trend in electronics and automotive sectors.

Hydraulic System Components and Functions

Hydraulic systems in injection molding machines deliver high force and precise control for key functions. Below are the main components, functions, requirements, and design considerations, with a focus on Indian applications.

Hydraulic Components

Pumps:

- Types:

- Variable Displacement Piston Pumps: Axial piston pumps (18–140 cm³/rev, up to 350 bar) for clamping and injection, offering adjustable flow for energy efficiency.

- Vane Pumps: Fixed or variable displacement (e.g., 10–100 cm³/rev, up to 250 bar) for screw rotation or smaller machines, cost-effective in India.

- Servo-Driven Pumps: Integrated with servo motors for precision and 40–60% energy savings, growing in hybrid machines.

- Requirements: Deliver 100–500 L/min flow and 150–350 bar pressure, with high durability for 10,000+ cycles/day.

- Design Considerations: Select pumps with 20% excess capacity for scalability. Use variable displacement or servo-driven pumps to minimize energy waste. Ensure compatibility with ISO VG 46/68 oils suited for India’s warm climate (25–40°C).

- Types:

Valves:

- Types:

- Proportional Directional Valves: 4/3-way valves for precise control of clamping and injection (flow rates 10–100 L/min, up to 350 bar).

- Servo Valves: High-response valves for injection accuracy (±0.1 mm/s).

- Cartridge Valves: Compact for ejection or core pulling, used in modular manifolds.

- Pressure Relief Valves: Limit pressure to 350 bar to prevent damage.

- Sequence Valves: Coordinate functions like ejection or core pulling.

- Check Valves: Prevent backflow in high-pressure circuits.

- Requirements: Fast response times (<50 ms), high-pressure rating (350 bar), and compatibility with closed-loop control systems.

- Design Considerations: Use proportional or servo valves for multi-stage injection profiles. Ensure tight tolerances in valve cavities to prevent leaks. Standardize valve interfaces (e.g., CETOP 3/5) for maintenance ease in India.

- Types:

Manifolds:

- Types:

- Custom Machined: Steel manifolds for high-pressure circuits (350 bar), integrating multiple valves to reduce piping, common in India for robust designs.

- Modular: CETOP 3/5 standards for flexibility, allowing valve replacement without system redesign.

- Cartridge Manifolds: Compact for auxiliary functions like ejection, widely used in India for cost-effective maintenance.

- Requirements: Support 150–350 bar pressure, minimize pressure drops (<5%), and accommodate multiple valve stations (4–10).

- Design Considerations: Optimize internal passages to reduce turbulence and heat. Use steel for high-pressure circuits and aluminum for low-pressure (up to 210 bar) to balance cost and durability. Include spare ports for future functions.

- Types:

Cylinders:

- Types:

- Clamping Cylinders: Large-bore (100–500 mm), double-acting for high-force mold closing (500–8000 tons).

- Injection Cylinders: Smaller (50–150 mm) for high-pressure injection (150–250 bar).

- Ejection and Carriage Cylinders: Small (25–80 mm) for low-pressure tasks (50–150 bar).

- Requirements: High force (20–1000 kN), precise stroke control (±0.5 mm), and wear-resistant seals (e.g., Viton, NBR).

- Design Considerations: Use double-acting cylinders for bidirectional control. Ensure seals withstand India’s high-cycle operations and temperature fluctuations. Integrate position sensors for closed-loop feedback.

- Types:

Motors:

- Types: Hydraulic vane or piston motors for screw rotation (100–500 Nm torque, 50–200 RPM).

- Requirements: Consistent torque for varying resin viscosities, low noise (<80 dB).

- Design Considerations: Select motors with high volumetric efficiency to minimize fluid waste. Use proportional flow valves for precise speed control.

Accumulators:

- Types: Nitrogen-charged bladder or piston accumulators for high-speed clamping or injection.

- Requirements: Store 1–10 L of fluid at 150–350 bar, rapid discharge (<100 ms).

- Design Considerations: Use accumulators for thin-wall molding to reduce cycle time. Ensure safety valves to prevent overpressure.

Hydraulic Fluid and Filtration:

- Fluid: ISO VG 46 or 68 oils with anti-wear additives, suited for India’s climate (25–40°C).

- Filtration: 10-micron absolute filters to prevent contamination, which causes 70–90% of hydraulic failures.

- Requirements: High thermal stability (40–60°C operating range), low viscosity variation.

- Design Considerations: Use filters with clog indicators for proactive maintenance. Select fluids compatible with seals and components to extend lifespan.

Reservoirs and Cooling:

- Reservoirs: 50–500 L capacity, depending on machine size, with air or water-cooled heat exchangers.

- Requirements: Maintain fluid temperature at 40–60°C, include level sensors and breather caps.

- Design Considerations: Design reservoirs with easy access for fluid replacement and cleaning, critical for India’s high-cycle operations. Use heat exchangers to manage heat in warm climates.

Main Hydraulic Functions

Clamping:

- Purpose: Closes, holds, and opens mold halves with high force to withstand injection pressure.

- Implementation: Large double-acting cylinders driven by a variable displacement piston pump (150–350 bar). A 4/3-way proportional valve controls speed and force, with accumulators for rapid closing in high-speed applications. Pressure relief valves limit force to protect molds.

- Requirements: High force (500–8000 tons), precise platen alignment (±0.5 mm), cycle times <5 seconds.

- Design Considerations: Use closed-loop control with position and pressure sensors. Optimize accumulator sizing for energy efficiency in India’s packaging sector.

Injection:

- Purpose: Drives the screw to inject molten plastic into the mold.

- Implementation: Double-acting cylinder (50–150 mm) powered by a piston pump (150–250 bar). Servo or proportional valves enable multi-stage injection profiles (fill, pack, hold), with accumulators for high-speed thin-wall molding.

- Requirements: High pressure (150–250 bar), precise speed (±0.1 mm/s), shot volume accuracy (±0.5%).

- Design Considerations: Integrate pressure transducers for real-time feedback. Design for rapid response (<50 ms) to meet India’s high-speed production needs.

Screw Rotation (Plasticizing):

- Purpose: Rotates the screw to melt and mix plastic resin.

- Implementation: Hydraulic vane or piston motor driven by a pump (50–150 bar) through a proportional flow valve at 50–200 RPM.

- Requirements: Consistent torque (100–500 Nm), low noise (<80 dB), high volumetric efficiency.

- Design Considerations: Use cost-effective vane pumps for smaller machines in India. Ensure motor durability for varying resin viscosities.

Ejection:

- Purpose: Pushes the molded part out of the mold after cooling.

- Implementation: Small double-acting cylinder (25–80 mm) driven by a low-pressure pump (50–150 bar) via a 4/3-way solenoid valve. Sequence valves coordinate with mold opening.

- Requirements: Precise stroke control (±0.5 mm), low force (5–50 kN).

- Design Considerations: Use cartridge valves in compact manifolds for cost-effective maintenance, common in India.

Carriage Movement:

- Purpose: Aligns the injection unit’s nozzle with the mold’s sprue bushing.

- Implementation: Double-acting cylinder (40–100 mm) driven by a pump (50–150 bar) through a solenoid valve, with position sensors for alignment.

- Requirements: Accurate positioning (±1 mm), moderate force (10–50 kN).

- Design Considerations: Minimize piping to reduce pressure losses, critical for India’s compact factory layouts.

Optional Hydraulic Functions

- Core Pulling: Actuates movable mold cores for undercuts using small cylinders (25–80 mm, 50–150 bar) and sequence valves, common in India’s automotive molds.

- Mold Unscrewing: Rotates mold cores for threaded parts (e.g., bottle caps) using hydraulic motors (50–150 bar) and flow control valves, popular in packaging.

- Mold Venting: Removes air/gases from the mold with hydraulic cylinders (50–100 bar) and solenoid valves, used in medical molding.

- Multi-Component Clamping: Supports multi-material molding with additional cylinders or rotary platens (150–250 bar), growing in India’s automotive sector.

- Mold Temperature Control: Dynamically heats/cools molds using hydraulic valves (50–100 bar) for high-gloss parts.

- Accumulator-Assisted High-Speed Functions: Uses accumulators (150–350 bar) for rapid clamping or injection, reducing cycle time in India’s packaging industry.

Common Specifications in Marketing Brochures

Specifications in India are presented in brochures to align with standards like ISO 20430:2020 and ISO 14829:2002, focusing on hydraulic system details for local customers. Common specifications include:

| Category | Parameter | Unit | Example |

|---|---|---|---|

| Clamping Unit | Clamping Force | kN | 600–33,000 |

| Tie-Bar Distance | mm x mm | 650 x 650 | |

| Mold Height (Min/Max) | mm | 200–600 | |

| Platen Size | mm x mm | 860 x 860 | |

| Opening Stroke | mm | 900 | |

| Injection Unit | Screw Diameter | mm | 40 |

| Shot Volume | cm³ | 200 | |

| Shot Weight (PS) | g | 750 | |

| Injection Pressure | bar | 2000 | |

| Injection Speed | mm/s | 200 | |

| Plasticizing Capacity | kg/h | 50 | |

| Hydraulic System | Pump Type | - | Variable Displacement Piston |

| Max Pressure | bar | 350 | |

| Flow Rate | L/min | 100 | |

| Fluid Type | - | ISO VG 46 | |

| Accumulator Capacity | L | 1–10 | |

| Valve Type | - | Proportional 4/3-Way, Cartridge | |

| Cylinder Size (Clamping) | mm | 100–500 | |

| Motor Type (Screw) | - | Vane or Piston | |

| General | Machine Weight | kg | 15,000 |

| Dimensions (L x W x H) | mm | 10,000 x 2,500 x 2,800 | |

| Noise Level | dB | <70 | |

| Cycle Time | s | 3 | |

| Control System | Control Type | - | Microprocessor-Based PLC |

| Precision Features | - | Closed-Loop, Adaptive Control | |

| Optional Features | - | - | Core Pulling, Mold Unscrewing |

| Standards Compliance | - | - | ISO 20430, IATF 16949 |

Best Practices for Hydraulic System Design

Hydraulic system design in India prioritizes affordability, reliability, and efficiency to meet high-cycle production demands. Below are key best practices with detailed considerations:

Maximize Energy Efficiency:

- Practice: Use variable displacement piston pumps (150–350 bar) or servo-hydraulic systems for 40–60% energy savings, critical for India’s cost-conscious market.

- Considerations: Select pumps with adjustable flow (e.g., 18–140 cm³/rev) to match demand. Use accumulators (1–10 L) for high-speed functions, reducing pump size. Optimize idle modes with bypass valves to minimize energy waste.

- Benefits: Lowers operating costs and heat generation.

Ensure Precision:

- Practice: Employ proportional and servo valves with closed-loop control for precise injection and clamping (±0.1 mm/s).

- Considerations: Use 4/3-way proportional valves for multi-stage injection profiles. Integrate pressure transducers and linear encoders for real-time feedback. Ensure valve response times <50 ms for India’s high-speed applications.

- Benefits: Reduces defects (e.g., flash, short shots) and improves repeatability.

Design for Reliability:

- Practice: Select robust components and implement contamination control for high-cycle operations (10,000+ cycles/day).

- Considerations: Use pumps and cylinders rated for 350 bar with wear-resistant seals (Viton, NBR). Install 10-micron absolute filters to prevent contamination. Use steel manifolds for high-pressure circuits to withstand India’s demanding production environments.

- Benefits: Extends component lifespan and reduces downtime.

Manage Thermal Loads:

- Practice: Minimize heat generation and maintain fluid temperature at 40–60°C.

- Considerations: Use air or water-cooled heat exchangers in reservoirs (50–500 L). Select ISO VG 46/68 oils with high thermal stability for India’s warm climate (25–40°C). Optimize manifold passages to reduce turbulence and heat buildup.

- Benefits: Prevents seal degradation and maintains performance.

Prioritize Safety:

- Practice: Incorporate safety features compliant with ISO 20430 and IATF 16949.

- Considerations: Install pressure relief valves (350 bar limit), emergency shutoffs, and lockout/tagout systems. Use guards for high-pressure lines and manifolds. Integrate pressure and temperature sensors with alarms for anomaly detection.

- Benefits: Enhances operator safety and regulatory compliance.

Simplify Maintenance:

- Practice: Design with modular components and diagnostic tools for India’s high-uptime needs.

- Considerations: Use modular manifolds (CETOP 3/5) and cartridge valves for easy replacement. Include test ports for pressure and flow diagnostics. Integrate IoT sensors for predictive maintenance, monitoring pump wear and fluid condition.

- Benefits: Minimizes downtime and repair costs.

Integrate Advanced Controls:

- Practice: Use PLC-based systems with adaptive algorithms for optimized hydraulic performance.

- Considerations: Implement microprocessor-based PLCs with touchscreen HMIs for real-time monitoring of pressure, flow, and temperature. Use adaptive control for resin variations, common in India’s diverse material applications.

- Benefits: Improves process consistency and reduces scrap.

Minimize Environmental Impact:

- Practice: Reduce fluid leaks and use eco-friendly fluids to support India’s sustainability goals.

- Considerations: Use precision-machined manifolds with O-ring seals to prevent leaks. Consider biodegradable fluids (e.g., synthetic esters) compliant with EU Ecolabel. Include spill containment trays around reservoirs.

- Benefits: Reduces environmental footprint and ensures compliance.

Optimize Manifold and Piping Design:

- Practice: Use compact manifolds and efficient piping to minimize pressure losses.

- Considerations: Design steel manifolds for high-pressure circuits (350 bar), reducing piping. Use short, high-pressure hoses with minimal bends (<5% pressure drop). Secure pipes with clamps to resist vibration in India’s high-cycle operations.

- Benefits: Enhances efficiency and reduces footprint.

Support Scalability:

- Practice: Design systems for future upgrades, such as additional core pulls or multi-component molding.

- Considerations: Include spare ports in manifolds for new circuits. Select pumps with 20% excess capacity (e.g., 120 L/min for a 100 L/min system). Use PLCs with expandable I/O modules for additional sensors.

- Benefits: Reduces upgrade costs and supports India’s growing automation needs.

Standards for Injection Molding Machines

Standards ensure safety, performance, and consistency in hydraulic system design, with India aligning with global and regional norms:

- ISO 20430:2020: Safety requirements for hydraulic, electric, and hybrid machines, covering guards, interlocks, and hydraulic pressure limits (350 bar max).

- ISO 14829:2002: Standardizes clamping force measurement (±2% accuracy).

- EN 201:2009: European safety standard, influencing Indian exports for CE marking.

- ANSI/SPI B151.1-2017: U.S. safety standard, relevant for machines exported to North America.

- IATF 16949:2016: Quality management for automotive, widely adopted in India’s automotive molding sector.

- ISO 50001:2018: Energy management for efficient hydraulic systems.

Specification Presentation Best Practices

Specifications in India are presented clearly to align with standards and meet local needs:

- SI Units: Use kilonewtons (kN), millimeters (mm), cubic centimeters (cm³), bars, and seconds, per DIN 24450.

- Tabular Format: Organize specs in tables for quick reference.

- Tolerances: Include accuracy ranges (e.g., ±2% for clamping force, per ISO 14829).

- Optional Features: List separately (e.g., core pulling, mold unscrewing).

- Standards Compliance: Reference ISO 20430, IATF 16949, or ANSI/SPI B151.1.

- Visual Aids: Include platen diagrams and hydraulic circuit layouts.